From a young age, engineer Mike Gruizinga has been fascinated with speed and racing.

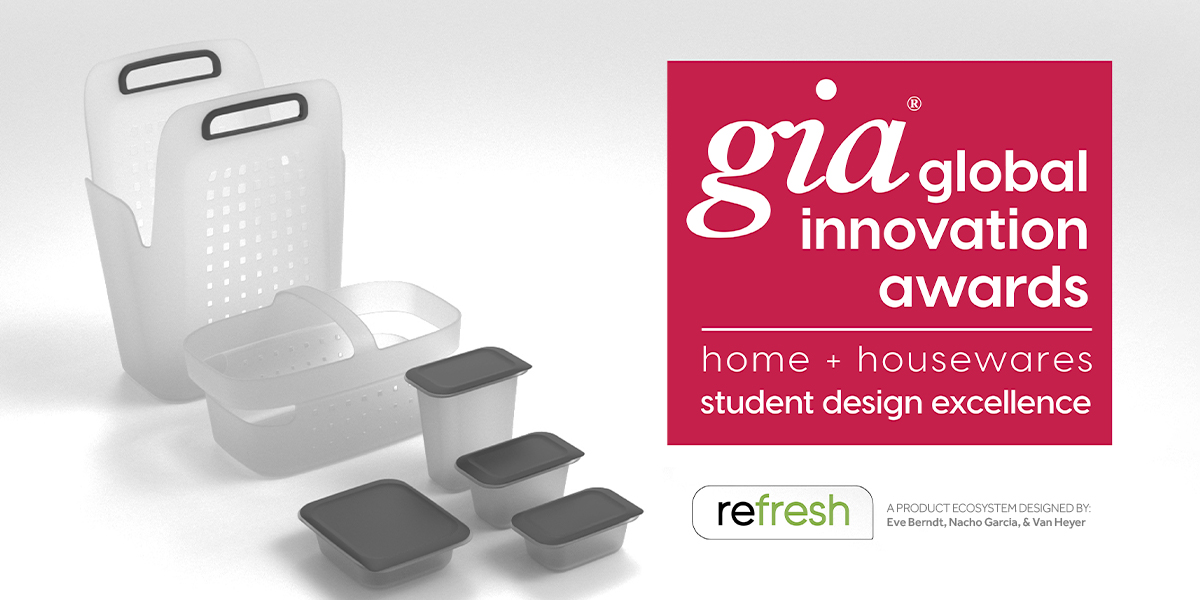

Continue readingGlobal Innovation Awards

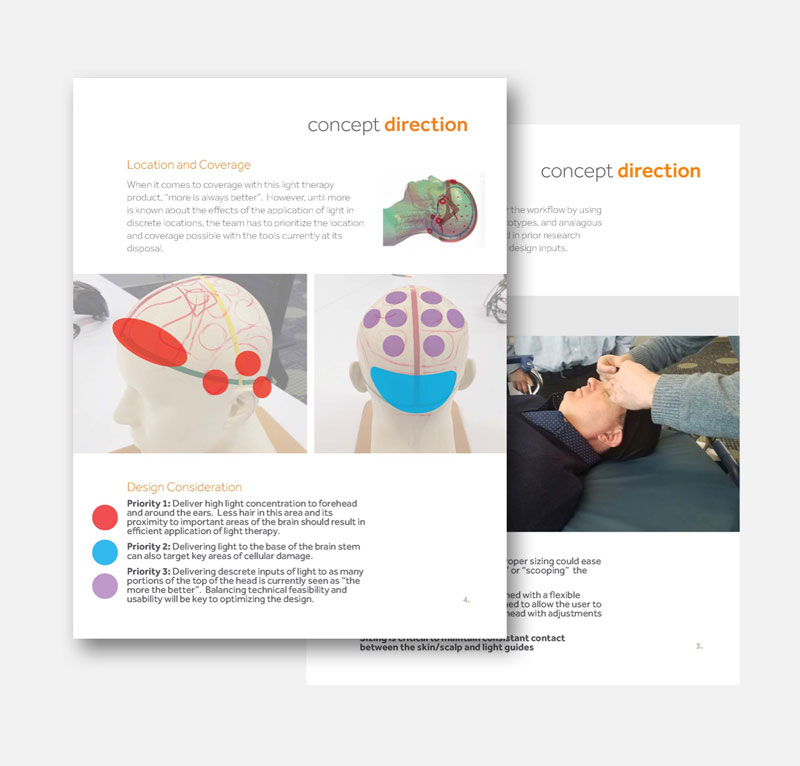

We are excited to celebrate the accomplishments of our very own Eve Berndt at the Global Innovation Awards!

Continue readingDigimate

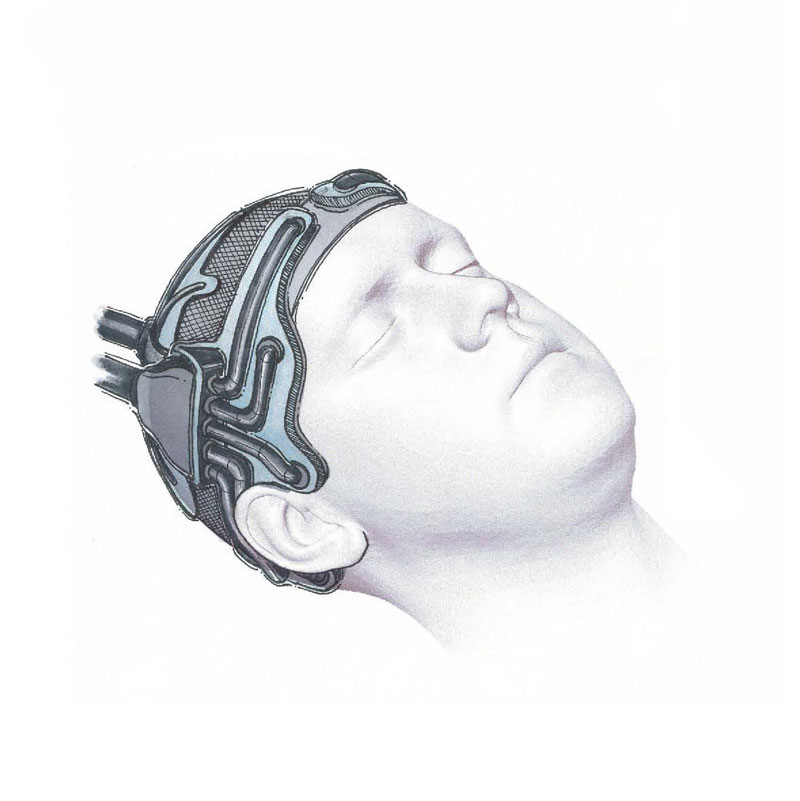

Responding to the Need – PPE for the COVID-19 Pandemic

We can’t express enough gratitude to all of the healthcare professionals working so hard to care for us in a great time of need!

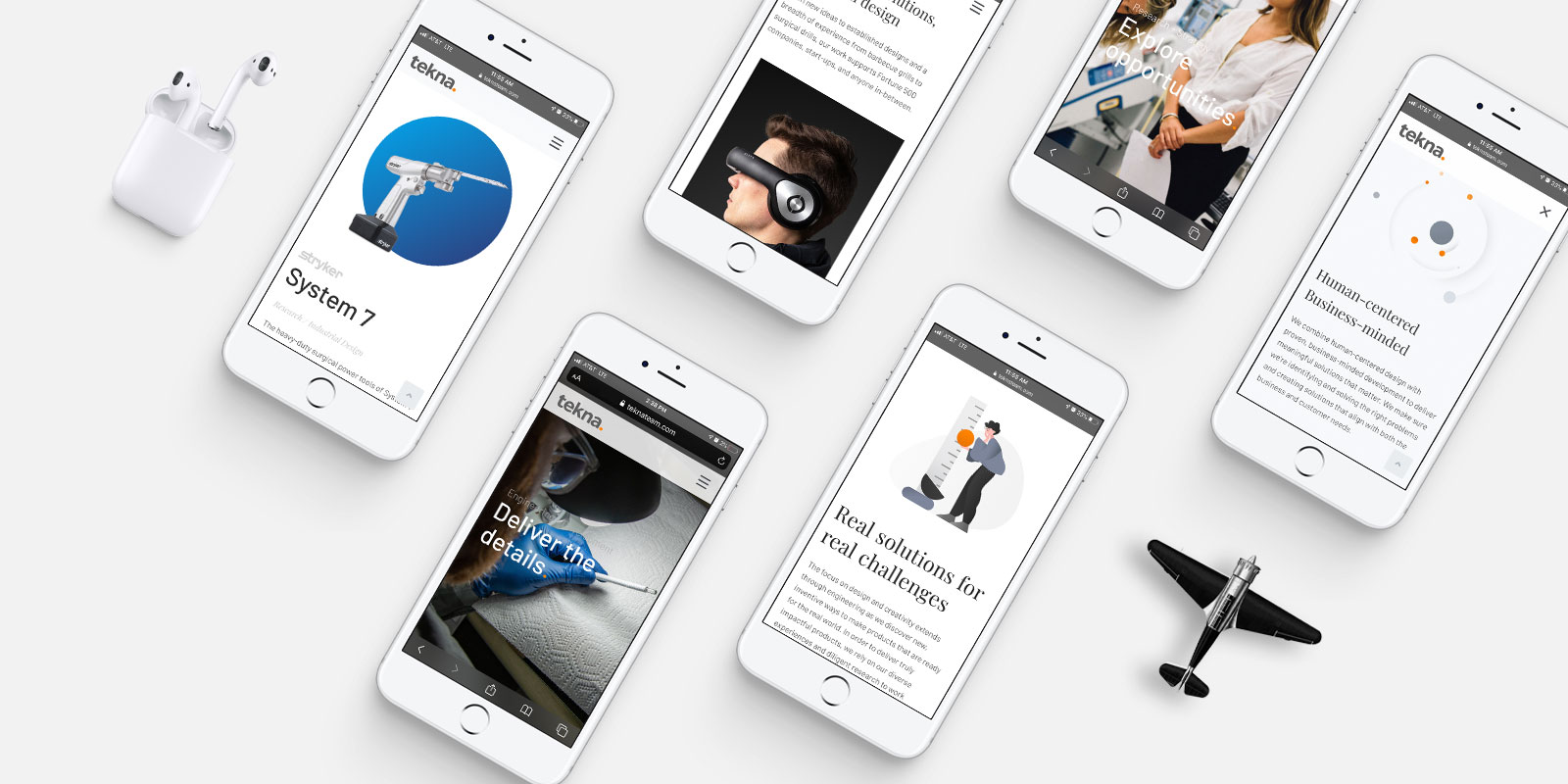

Continue readingNew Year, New Look, New Website

It’s hard to believe it’s been four years since we launched our rebrand and new website. At the same time, it feels like it’s exactly who we’ve always been.

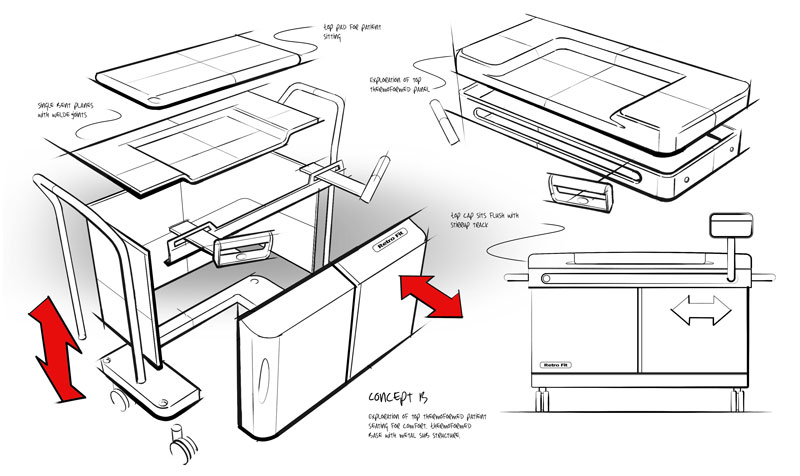

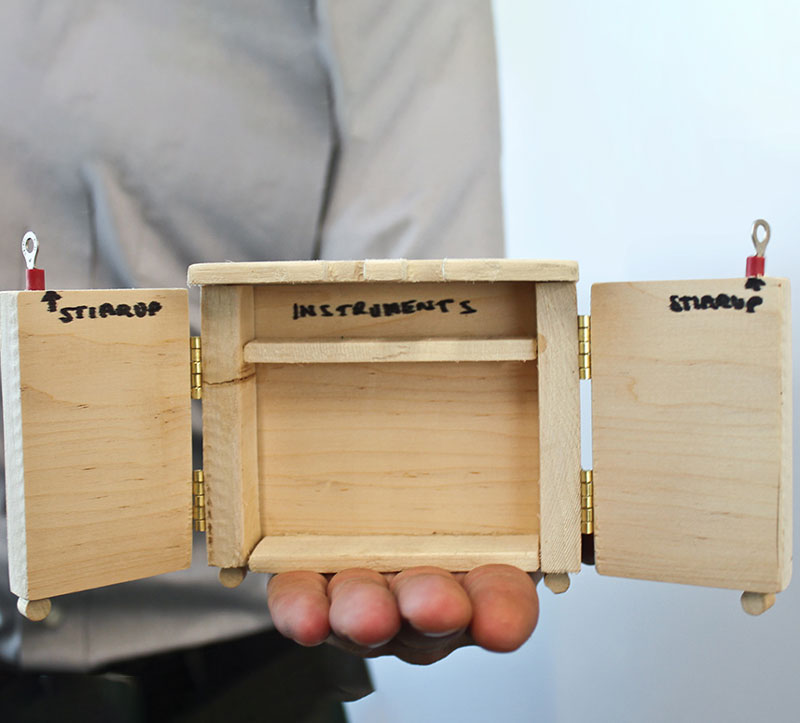

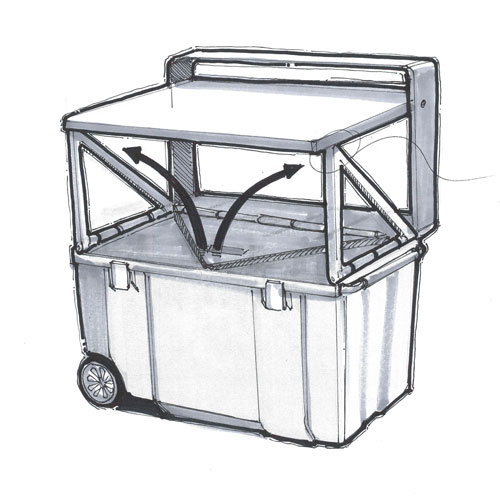

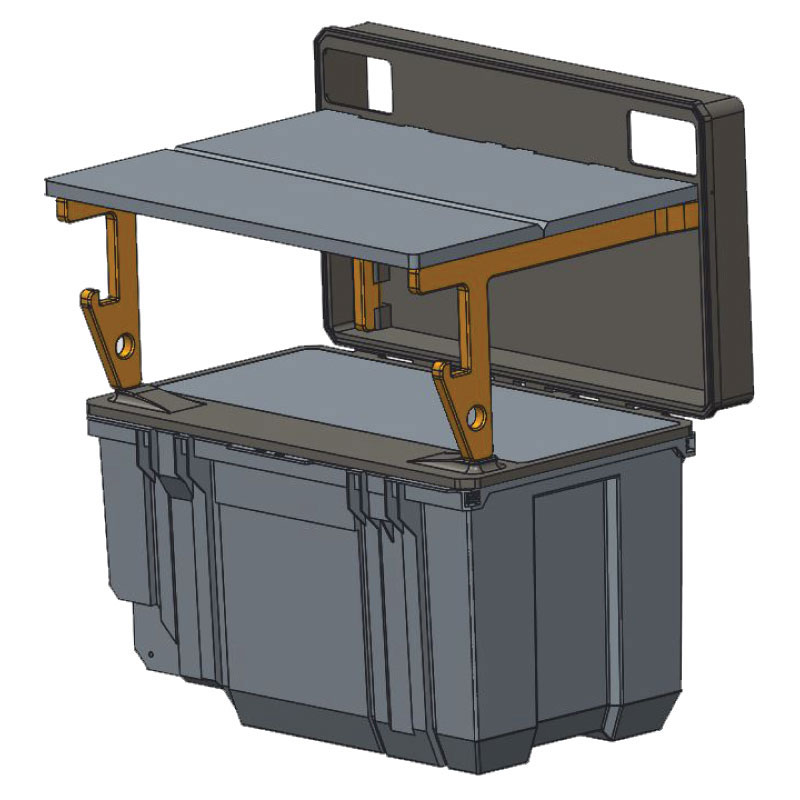

Continue readingRetroFit Cart

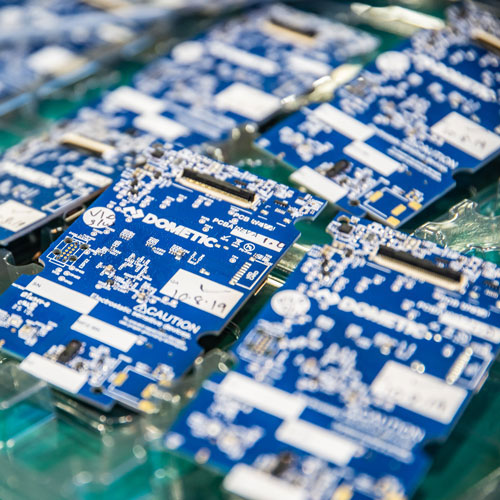

IoT Controller

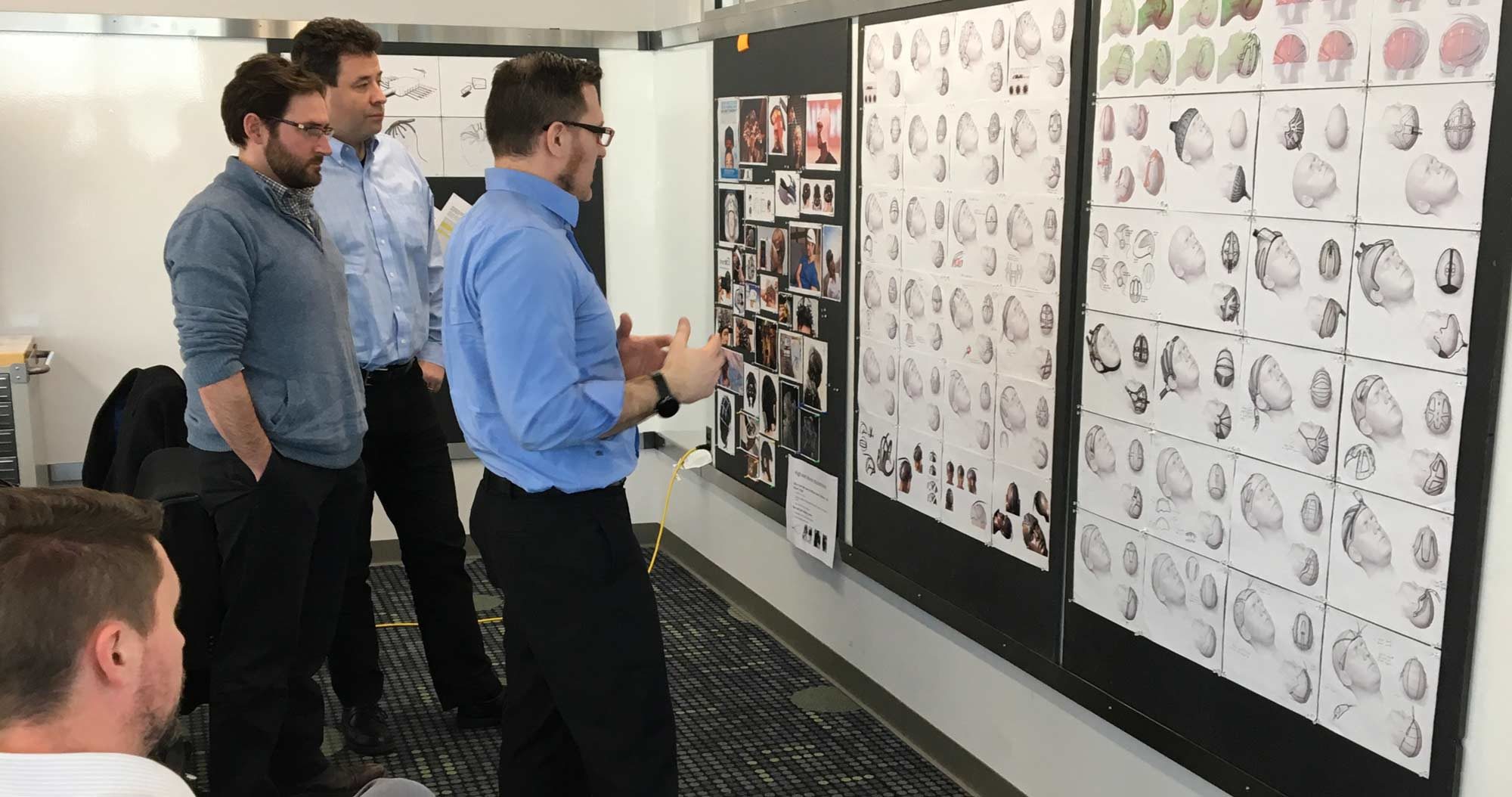

Tekna Awarded Wonderful Workplace

Tekna was selected by 269 Magazine as one of Southwest Michigan’s Wonderful Workplaces.

Continue reading