Ignite

Ignite

Branding / Industrial Design / Animation

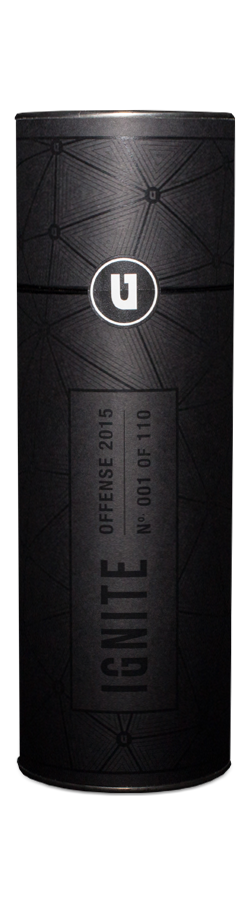

In an effort to inspire key business, marketing, and R&D leaders, we were hired to develop the branding and experience design for several annual strategy meetings. The brand needed to rally the division behind a new framework for the business along with communicate the goals for the following year.

Ignite was conceived to embody the idea that even seemingly singular events have large, dedicated teams passionately working together to accomplish a common goal.

Through video, transition infographics, voice overs, and supporting 2D materials, we were able to carefully craft a final experience that would captivate and inspire the audience.

A specially designed, limited edition memento was handed out after the presentation to remind the team of their commitment and allow them to report back to their teams and “unite to ignite.”

Glyph

Glyph

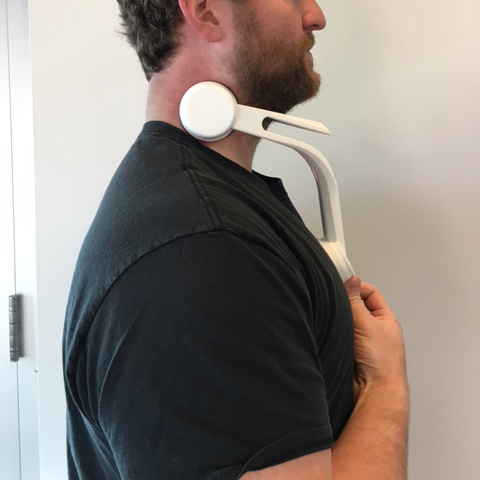

Industrial Design / Human Factoring / Engineering

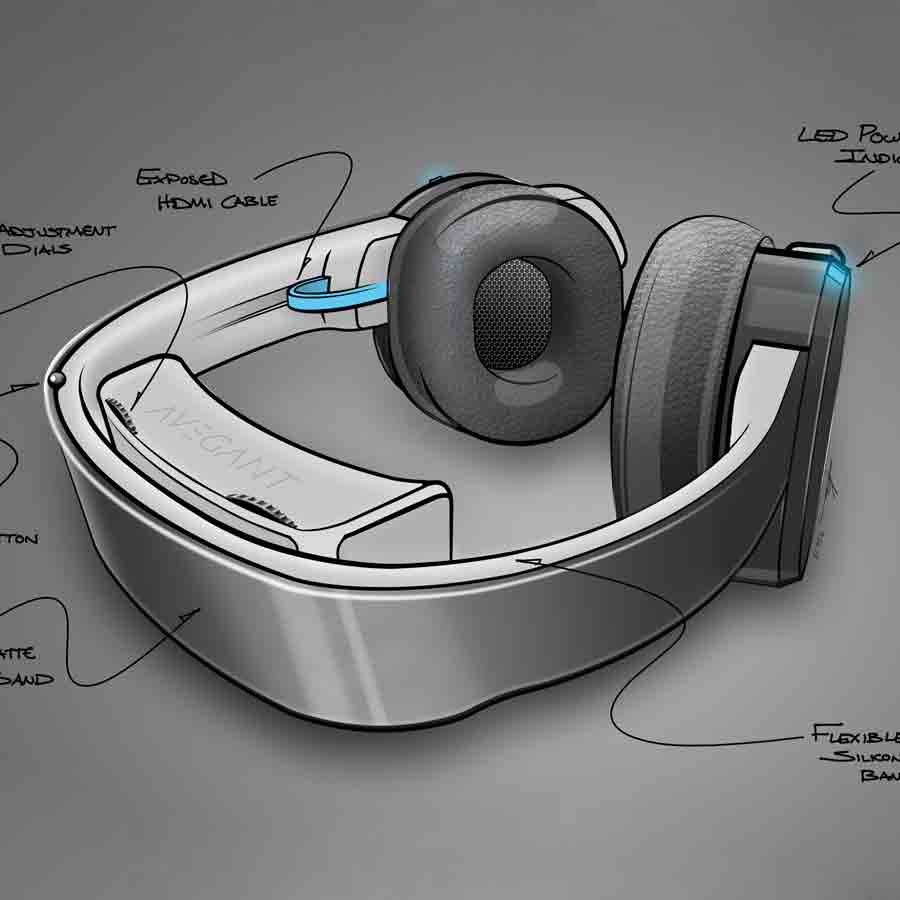

Avegant’s Glyph is the world’s first personal theater designed with lightweight portability, rich audio, and amazingly precise video. We worked with the Avegant team to provide ergonomic adjustments and industry-leading aesthetics.

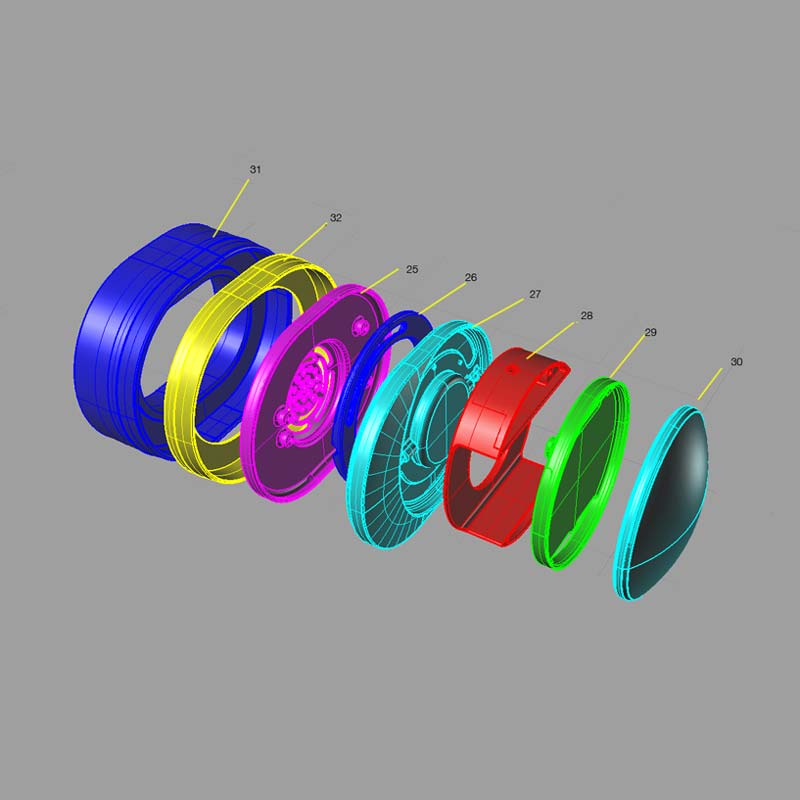

Avegant’s proprietary display technology is really not a display at all. An image is projected directly onto the user’s retina through millions of micromirrors and reflected light. This technology replicates the way we see and interpret the world around us, thus creating the most natural and comfortable viewing experience on the market.

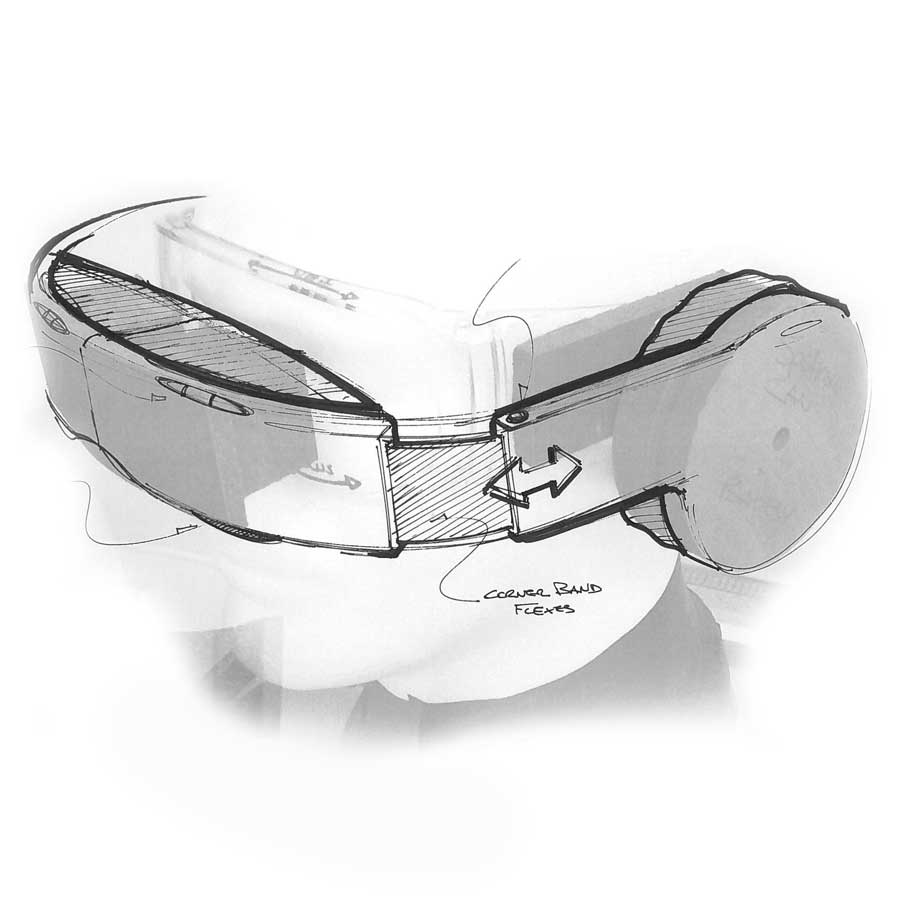

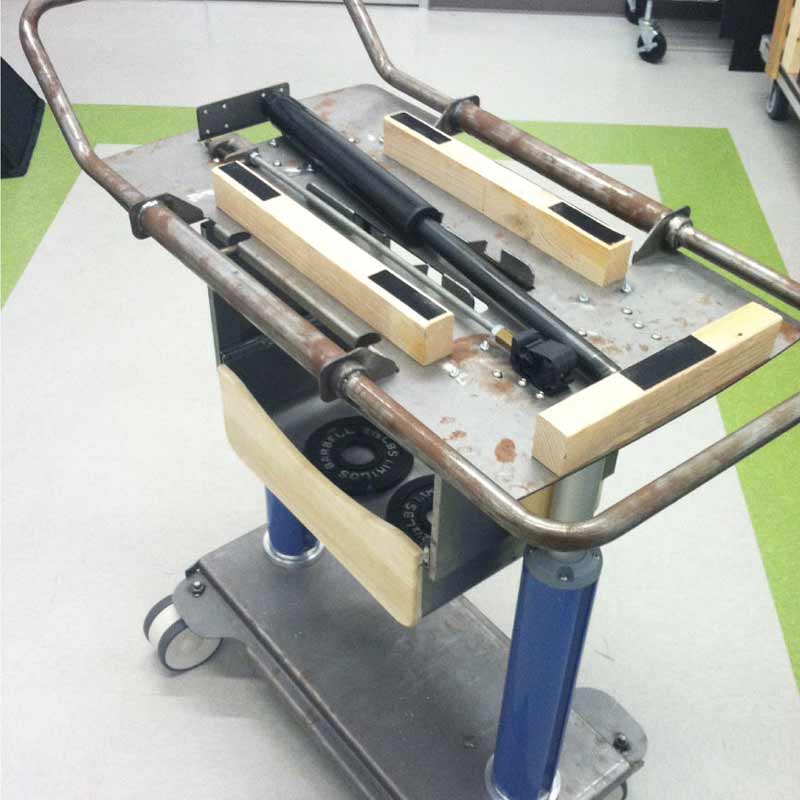

The functional engineering prototype, affectionately named the “steampunk proto,” provided an excellent demonstration of the Glyph’s core virtual retinal display technology. This prototype lacked user-friendly ergonomic adjustments and a desirable form factor.

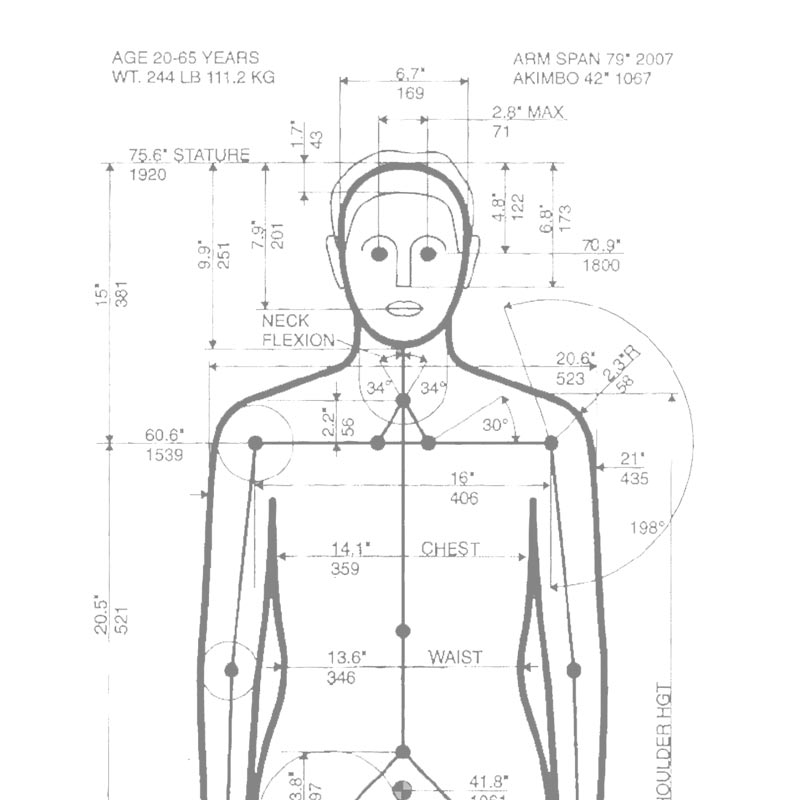

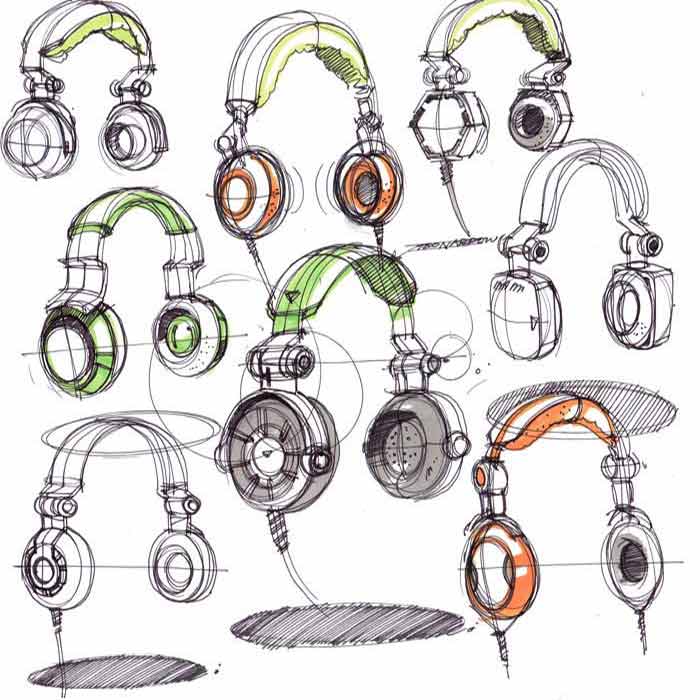

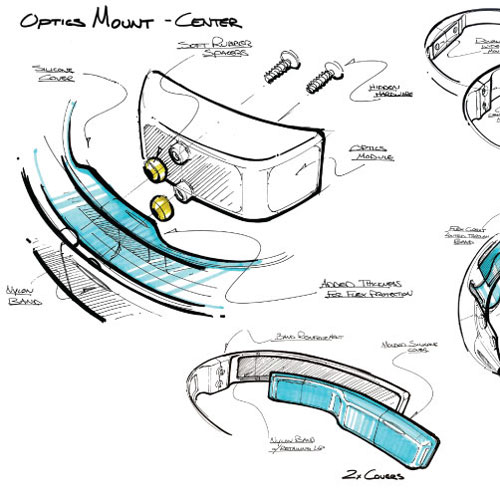

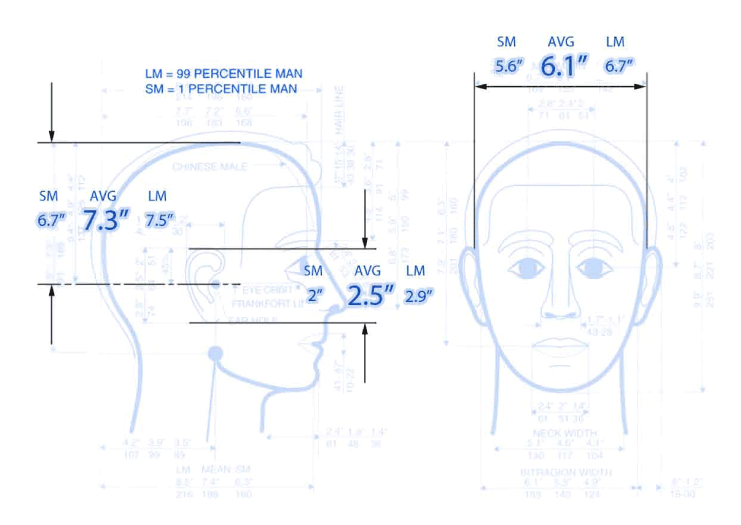

With the optics and circuit boards undergoing a new round of development at Avegant, we focused initial efforts on adjusting the headset to fit a wide range of head shapes and sizes. Critical anthropometric data were collected and studied and user studies were performed to refine interaction positions and inputs.

Our goals were reliability, comfort, and style. After the basic prototype direction was defined, detailed part-design and assemble methodology was explored. Throughout the process, there was a concentrated effort to maintain a robust design and yet reduce size, weight, and part count.

Other team members benchmarked competitive product by exploring design elements, materials choices, manufacturing methods, and branding messages. This research, along with input from Avegant, served as the foundation for the Glyph’s personality and aesthetic development.

Several rounds of detailed part assemblies were built with parametric modeling software. Each round concluded with rapid prototyped, proof-of-concept models tested by users, media, and investors across the country. The acoustic cavity received additional attention from partners in California and Austria to define Avegant’s signature sound and noise cancelation system.

The revolutionary technology and user adjustment challenges meant that this system could only be designed from the inside out. Unique mechanisms allowing smooth interpupillary distance and diopter lens adjustments were created and then carefully packaged within the global design. Those adjustments were critical to aligning the micromirrors with the user’s retina. Without proper positioning, the viewing experience was compromised. Circuit boards were strategically positioned for performance, interaction, and system balance. Cables and wires were precisely routed, service loops were created and strain reliefs provided. The assembly of each subsystem was carefully planned.

Once the optics and circuit boards for the International Consumers Electronics Show prototypes were defined, the final aesthetic details were established. Renderings were created to communicate form, color, finish, and material. An international press release introduced these early images of the Glyph Alpha to the world.

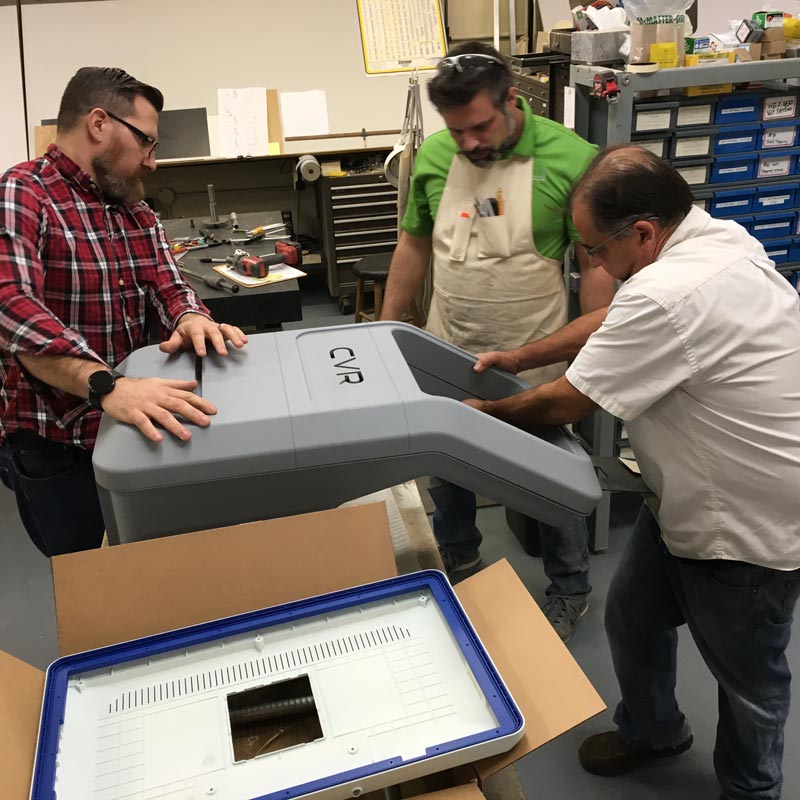

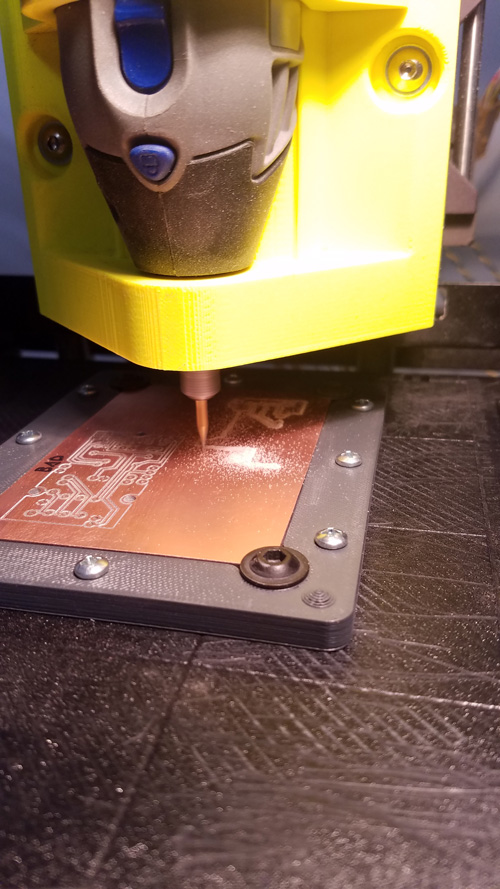

A month before the deadline, a test build was conducted in Austin, Texas. After two days, 43 necessary changes were identified and after an intense week of design, final part files were released for fabrication. CNC machines were fired up, 3D printers were initialed, and model makers were prepared. With over hundreds of parts to fabricate, this project required the orchestration of many partners to ensure delivery of successful prototypes.

Two weeks after releasing data, Avegant and Tekna team members gathered to build the first of 12 functional prototypes. After 16 hours of concentrated effort, the first working Glyph Alpha was born. In two more build sessions lasting several days (and nights), additional improvements were added. Finally, the remaining Alpha units were completed, tested, and released for the show.

Success was realized at CES as the Glyph received massive media attention. Reviewers raved about the Glyph’s revolutionary technology and superior performance.

Best of CES 2016

The team took home a CES Editor’s Choice Award and a video spot on USA Today. Since then, the Glyph has evolved and went on to win the Best of CES Award in 2016.

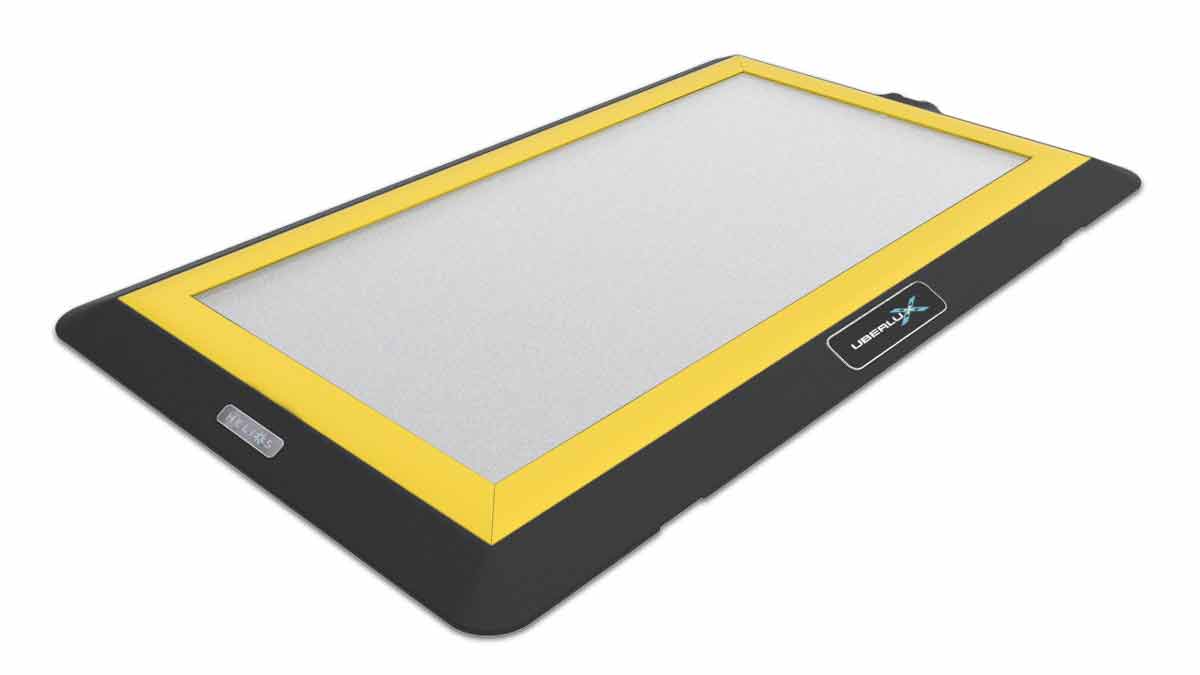

Helios

Helios

Branding / Graphic Design / Engineering / Production

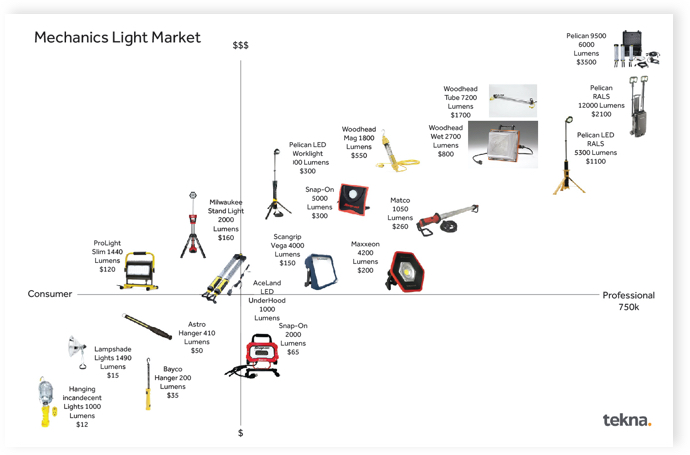

For professionals in the vehicle maintenance and inspection industry, having proper, hands-free illumination directly translates to improved safety and efficiency.

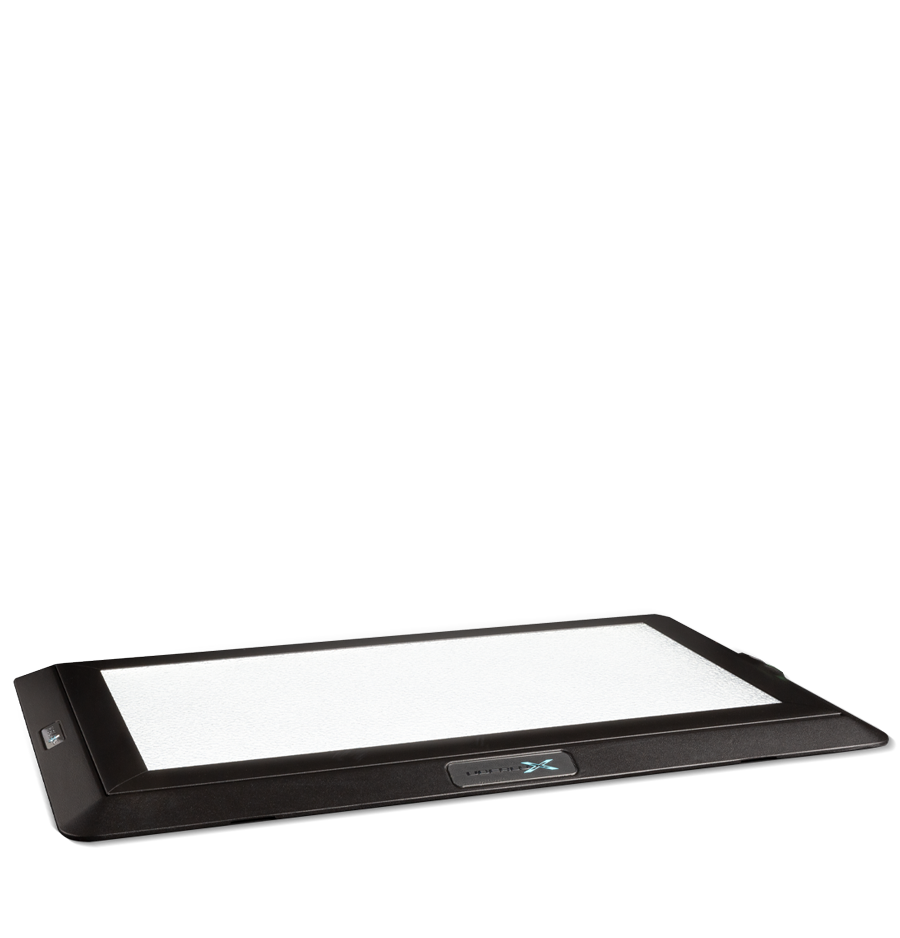

Helios by Uberlux is a low-profile work panel featuring the latest in LED technology for use in under-vehicle maintenance, inspection, and decorative illumination. Helios has a wide variety of applications in the automotive maintenance, military, and government industries.

DCI Lighting came to us with detailed working prototypes of the Helios concept, requesting design for manufacturing support to help move it to production. We provided a range of design and manufacturing services, ultimately helping them deliver a consistent, high-quality and well-branded product ready to make market waves in the extreme environments for which it was built.

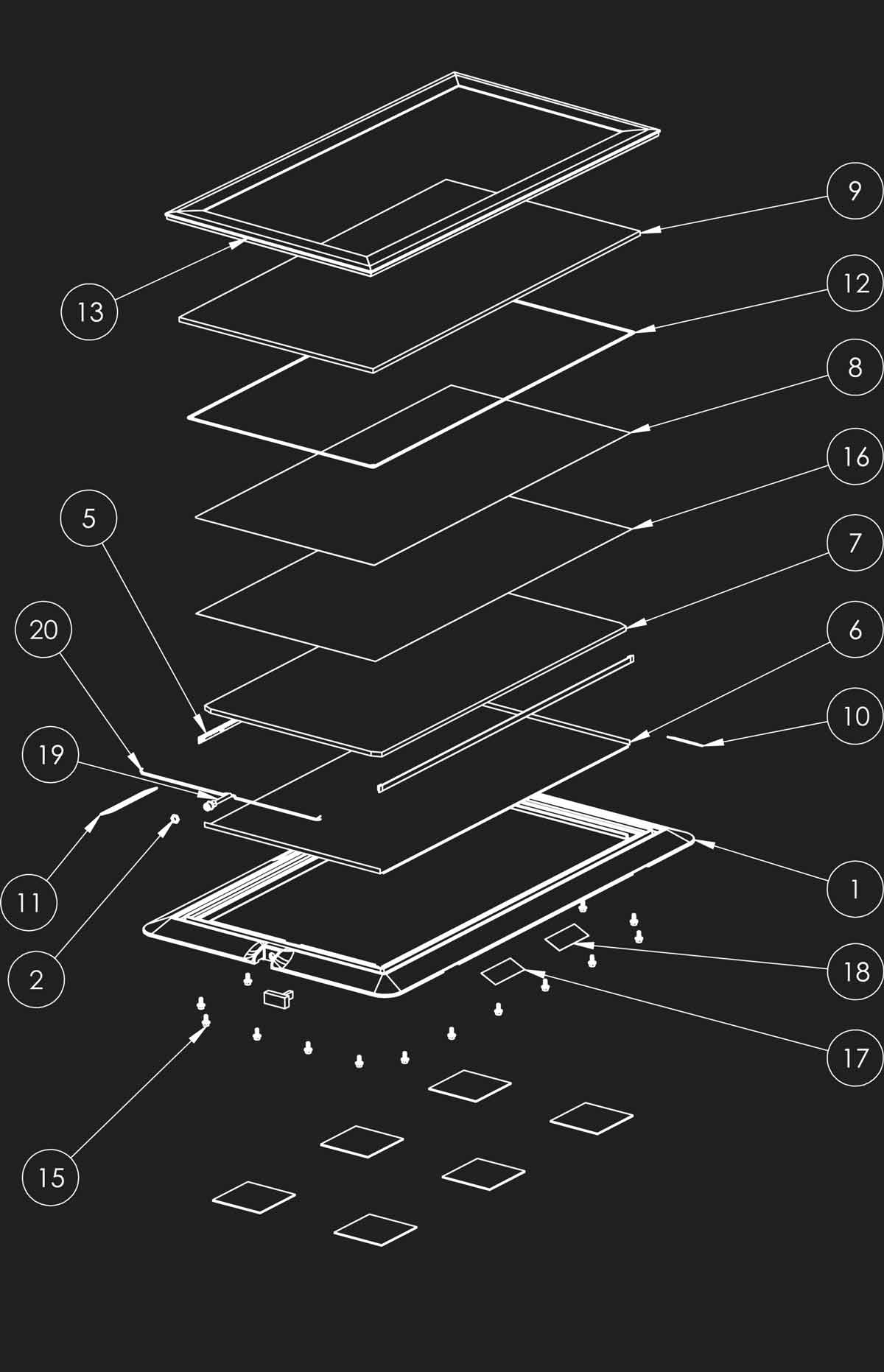

With key performance indicators top of mind (impact and fluid resistance plus the ability to support 15 tons of pressure), we embarked on our rigorous risk evaluation process. We found ways to make the unit more robust and reliable by reconstructing the light lens for safer compression and reconfiguring the seals for better fluid resistance and serviceability.

Key design elements to communicate a brand’s story. With some forethought, this can be done without adding significant cost to the product. Graphic identity, badging, packaging, and IFUs convey quality, value, and connect with a consumer on an emotional level.

While engineering testing was underway, our brand team was able to look at the overall visual identity and suggest ways to improve strategic messaging. We developed a brand hierarchy, logos, badging, packaging, and marketing collateral that aligned with the product’s value proposition.

As we moved closer to product launch, digital material, website, e-commerce, and social media became key deliverables, centered around the positioning statement “Lighting Reinvented from the Ground Up.”

The product was officially unveiled at the 2018 SEMA Show in Las Vegas, with a custom trade-show booth designed to immerse visitors in the context and environment of a professional garage, featuring a full-size display of the undercarriage of an automobile. Looping videos with early end-customer research further enhanced the Helios story.

As a design-focused company, we want the line to be as innovative as the product we are building. Always focused on staff safety and ergonomics, lines are designed and organized for the proper height, optimal reach with minimal movement, and, of course, ample lighting. This also ensures that we consistently and efficiently produce a high-quality product.

For this line, we used sleek black work surfaces with modular aluminum structures. Production fixtures were designed to quickly maneuver between both sides of the light panel. We developed a solution that resembled an industrial Belgian waffle maker that allows access to the panel’s top and bottom while compressing the components as they are fastened together. Additionally, we built custom ergonomic tools to make fastening motions safer and easier for production staff.

With the line and assembly details squared away, we implemented quality control measures and finalized logistical and distribution support. This allowed DCI Lighting to hit the ground running with seamless integration for e-commerce orders.

Helios won a Global Media Award at the PRI Show in 2018 and has been featured on MotorTrend TV, MAVTV, and Rev’n.

Sharpie Packaging

Sharpie Packaging

Industrial Design

Working alongside the design team of Newell Brands, we explored and executed packaging design solutions for Sharpie’s new line of Art Pens. The final solution incorporated new elements of their visual brand language and provided additional functionality – a case that could double as a stand.

The result? A versatile, streamlined solution: the hinged base flips back, converting to an upright easel for quick access to the pens, then collapses flat for easy storage. The durable, clear front pocket keeps the bold palette of 16 bright colors on full display — ready to elevate the artwork of pros and amateurs alike.

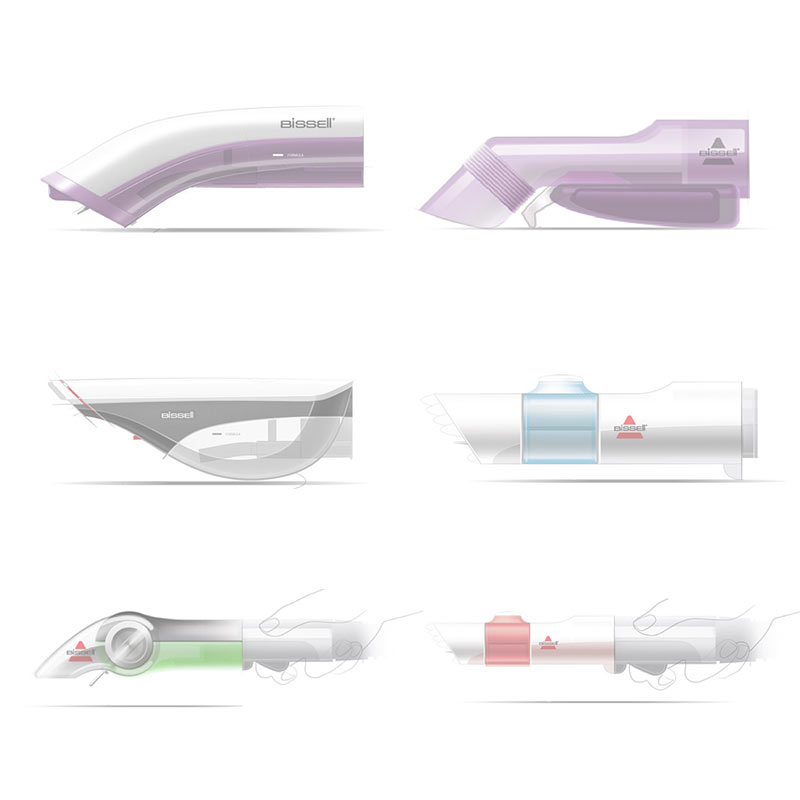

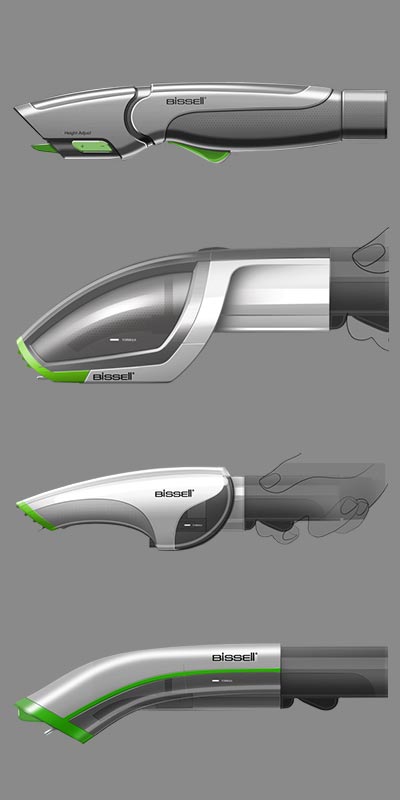

Barkbath

Barkbath

Industrial Design / Engineering

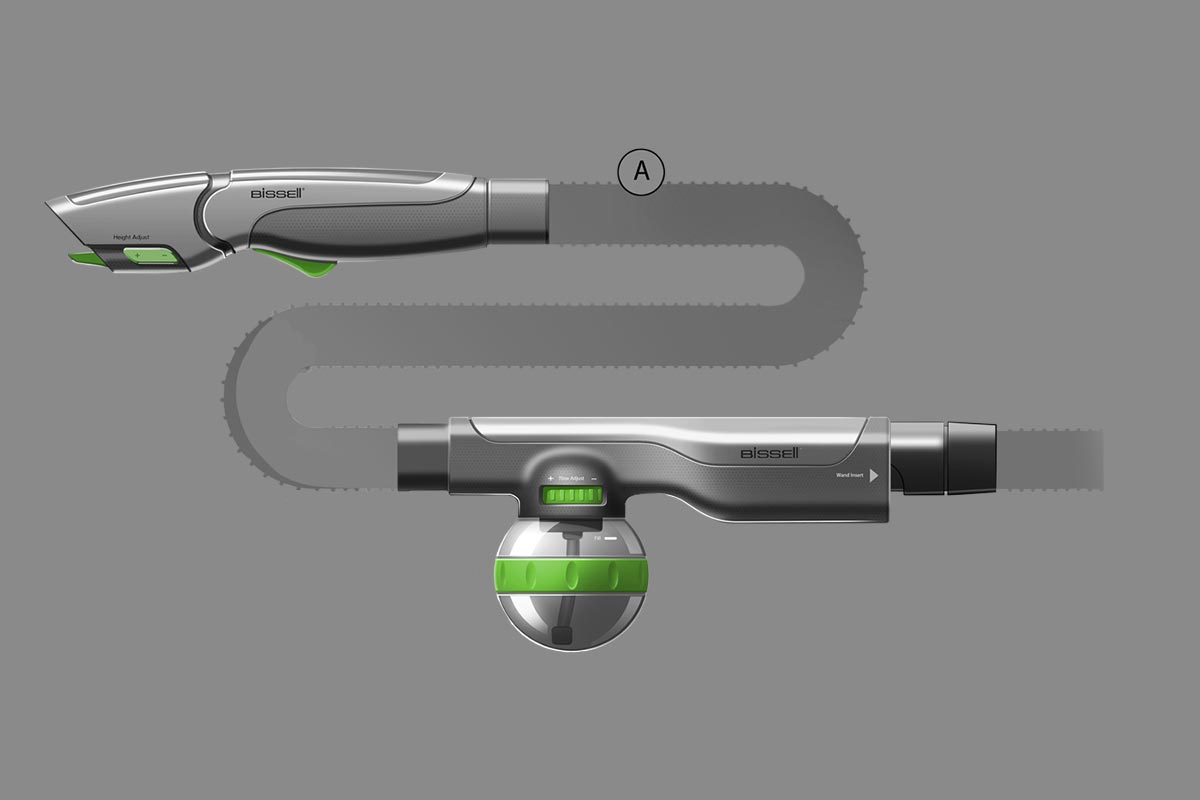

Users can now bathe their dog virtually anywhere with the mess-free BARKBATH portable bathing device. We helped develop the system’s convenient one-step wash/dry process that vacuums up a combined water/shampoo solution in a natural “petting” motion.

The unique nozzle gets beneath the animal’s fur, lifting away dirt and separating the dirty water into a clear tank where effectiveness is easily observed. The result? A cleaner, happier dog and drier owner—all while consuming dramatically less water (a 40-oz. supply of clean water will completely wash an 80-lb. dog, versus a traditional bath that can use up to 19 gallons).

Prototypes were demoed at Bissell’s Pet Spot (a four-stall kennel inside the corporate building allowing staff to bring their pets to work). Not only did the experience underscore the company’s commitment to employees and their Pet Foundation, it also encouraged owners to try new pet products. Staff members would eagerly volunteer their dogs for trials, which meant we got to meet a lot of great dogs and owners. Some of the dogs are already the stuff of legend, namely the chief chemist’s 180-lb Alaskan Malamute, Chief.

To deliver a prototype quickly, we used as many current parts as possible, opting to pair an available venturi (which can mix water and shampoo from a reservoir) with the existing trigger shut-off valve. These parts were never intended to function together, so packaging them to work in the smallest space possible was challenging. We started with a rough mock-up to engineer the hydraulic circuit. After the circuit was proven successful, we began the iterative process of developing an attractive housing for everything.

What makes us most proud is how we advanced the concept past the initial expectation, delivering a solution that satisfied their specifications in an integrated, elegant format that was not originally considered.

Bark Bath Portable Dog Bath received a Good Design Award from Chicago Athenaeum: Museum of Architecture and Design and was also a finalist in the 2017 International Design Excellence Awards.

Nara

Nara Bassinet

Research / Human Factors / Industrial Design / Branding / Animation / Engineering / Production

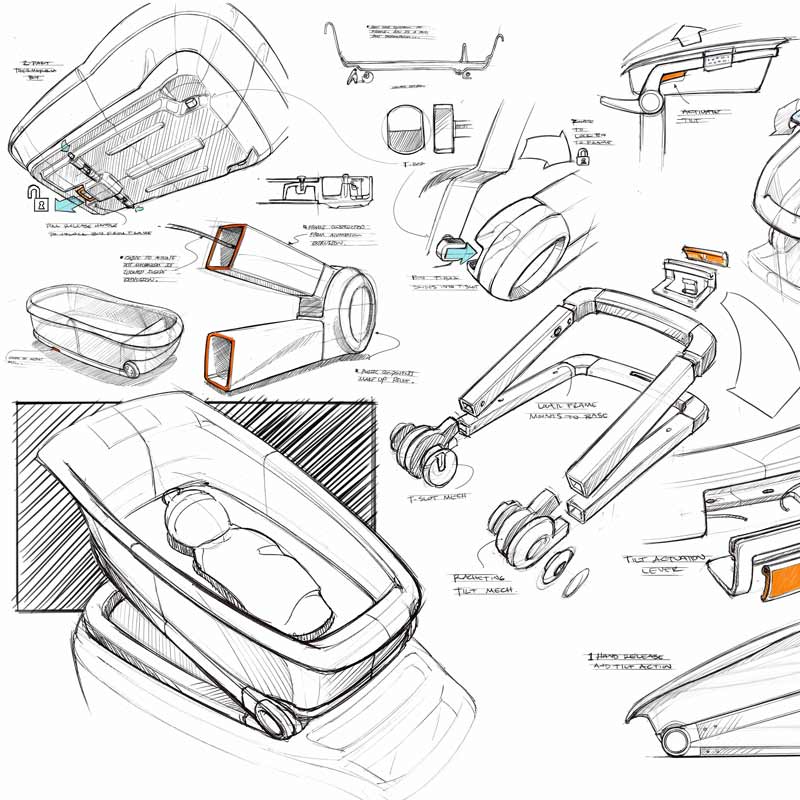

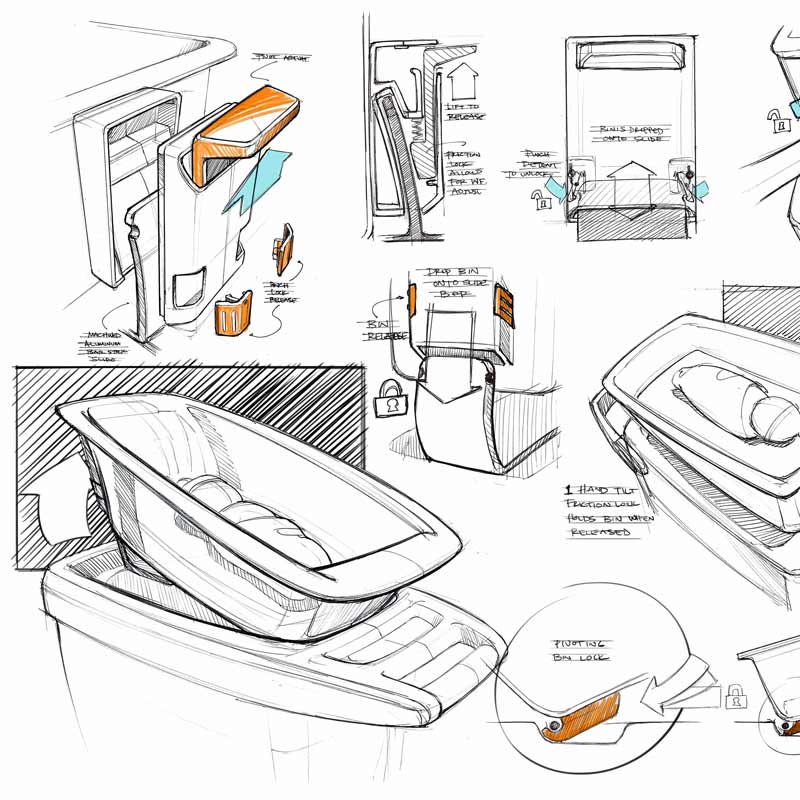

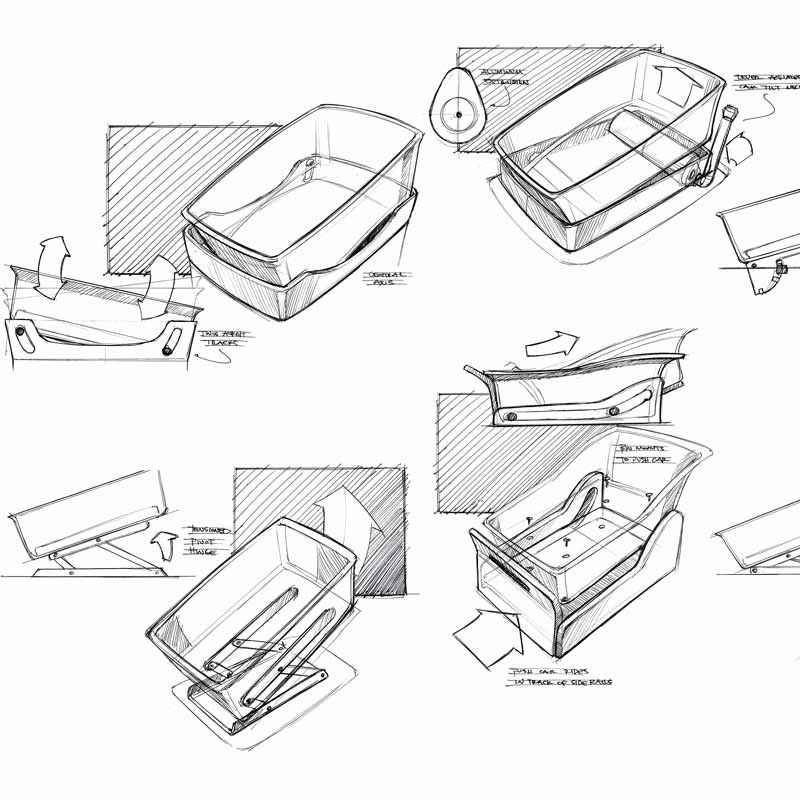

Nara is our baby. It was internally created from the ground up as a new, innovative hospital bassinet. It was designed to bring mothers close to their newborns when it matters most and provide caregivers with a beautifully designed, safe, ergonomic care solution

We recognized that the bassinet market has been relatively ignored for decades. Current bassinets could be described as one of two things: a wood filing cabinet or a metal filing cabinet on wheels. We started to ask the question, why are we pushing newborn babies around on filing cabinets?

We started our research at the source – with NICU and mother/baby nurses. We heard complaints of bulkiness, uncleanliness, and inaccessibility that added up to an experience that was just plain clunky. We studied each person’s interactions and allowed their feedback to evolve our design. Some nurses were stooping and straining too much, others struggled to quietly and efficiently maneuver the bassinet, and mothers had trouble reaching for their babies from bed. It was clear we needed to develop a new solution.

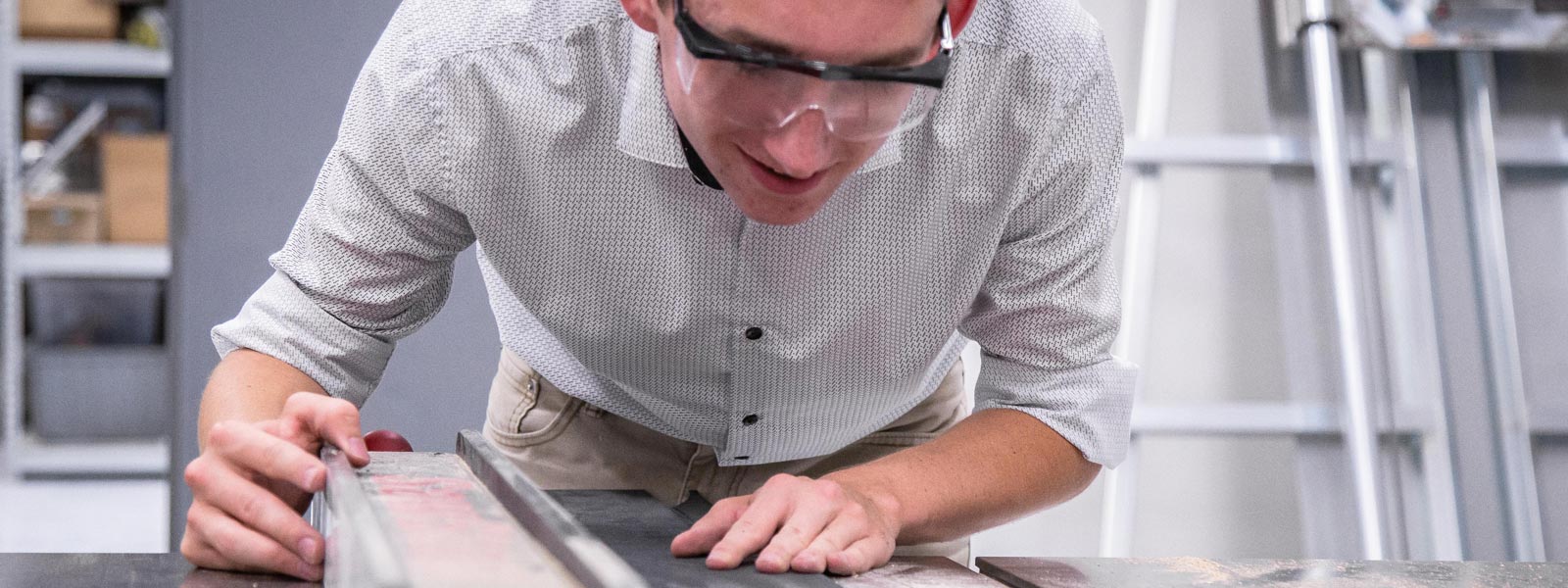

We implemented our iterative prototyping processes and leveraged sketch exploration, CAD development, in-house 3D printing, and fabrication methods to refine the aesthetic and functionality.

We conducted one-on-one user interviews, focus group discussions, and took full-scale mockups into the field to get feedback from people who would use this product every day.

We conducted comprehensive formative and summative usability testing with Labor/Delivery and NICU nursing staff, hospital environmental services, and new moms. Their overwhelmingly positive responses validated the final design and new features.

As the product evolved, so did the brand, differentiating it in the market as approachable, caring, and inviting. Branding efforts included print material, animation, and video creation. The true value of experience that we were reinventing was taking shape but it needed a name, and ultimately we had to look outside the English language to capture its essence – Nara.

Nara received a Good Design® Award from Chicago Athenaeum: Museum of Architecture and Design, as well as the Core77 Community Choice Prize, and a 2017 Core77 Notable Award in the Commercial Equipment category.

Altogether, initial user research, opportunity identification, and industrial design grew to mechanical engineering, regulatory support, branding, and manufacturing for a Class II medical device. The exciting value propositions presented by our end product captured the interest of a major medical device manufacturer that led to an OEM opportunity for us. Our team ensured every bit of design intent was captured when we brought the product to life and delivered a solution that’s locally designed and manufactured, leveraging a supply chain based predominantly in Michigan.

Timberline

Timberline

Research / Industrial Design / Engineering / Production

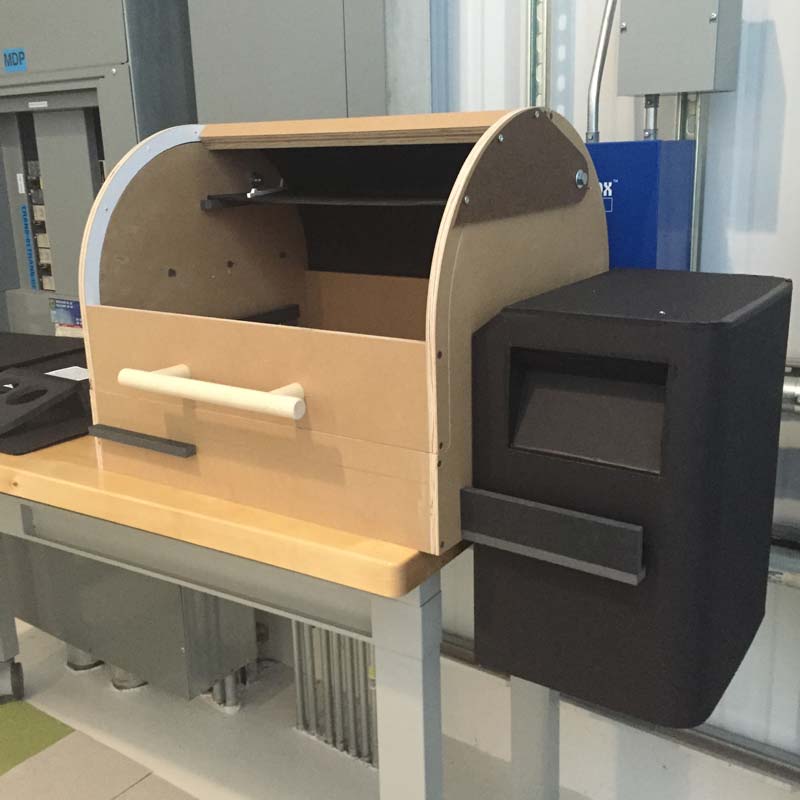

We were challenged with helping Traeger’s vision to develop a new flagship grill with improved craftsmanship, reimagined aesthetics, an advanced, wifi enabled user interface, improved cooking performance, and a cooking capacity for a family to cook a complete meal.

We conducted secondary research on BBQ and pellet grills collecting competitive information and spending time in the field. The highlight of our field research came from interviews with leading industry influencers such as Danielle Bennett (Diva Q) and Cameron Treu (Bam Bam). We even participated with Bam Bam at the Nevada State BBQ Championship (Best Dam BBQ Challenge). These discussions and insights from observing what it takes to make great BBQ, led us to hypotheses on the science of smoke and smoke utilization as well as the BBQ culture and a griller’s expected experience.

The team established methods to investigate and measure their hypothesis around smoke utilizations and proof of function prototypes were fabricated and data was collected and analyzed to help guide the team toward appropriate solutions.

To ensure the aesthetic was hitting the mark, multiple iterations of mock-ups were presented to research participants to gather end-user feedback and ensure we were delivering on Traeger’s brand value and the executive team’s goals.

The WiFire system allows the grill to be an IoT device, with the cloud server and app-based remote control. Our design team led the GUI development, managing the workflow, language, and graphics for what might be the most advanced grill control in the industry.

Timberline received a Good Design® Award from Chicago Athenaeum: Museum of Architecture and Design as well as the Gold award from AmazingRibs.com, the most influential BBQ website in the world.

Being the First Supply Chain Intern

When it came time to look for a summer internship, I really wanted to find something that would help me explore.

Continue readingWhen Life Gives you Lemons

About 2 years ago I tried to shoe ski down a huge, snowy, slick hill on my way to class (as any college kid would)

Continue reading